| unit: | |

|---|---|

| Size: | |

| Availability: | |

4000-6000GSM

Yingfan

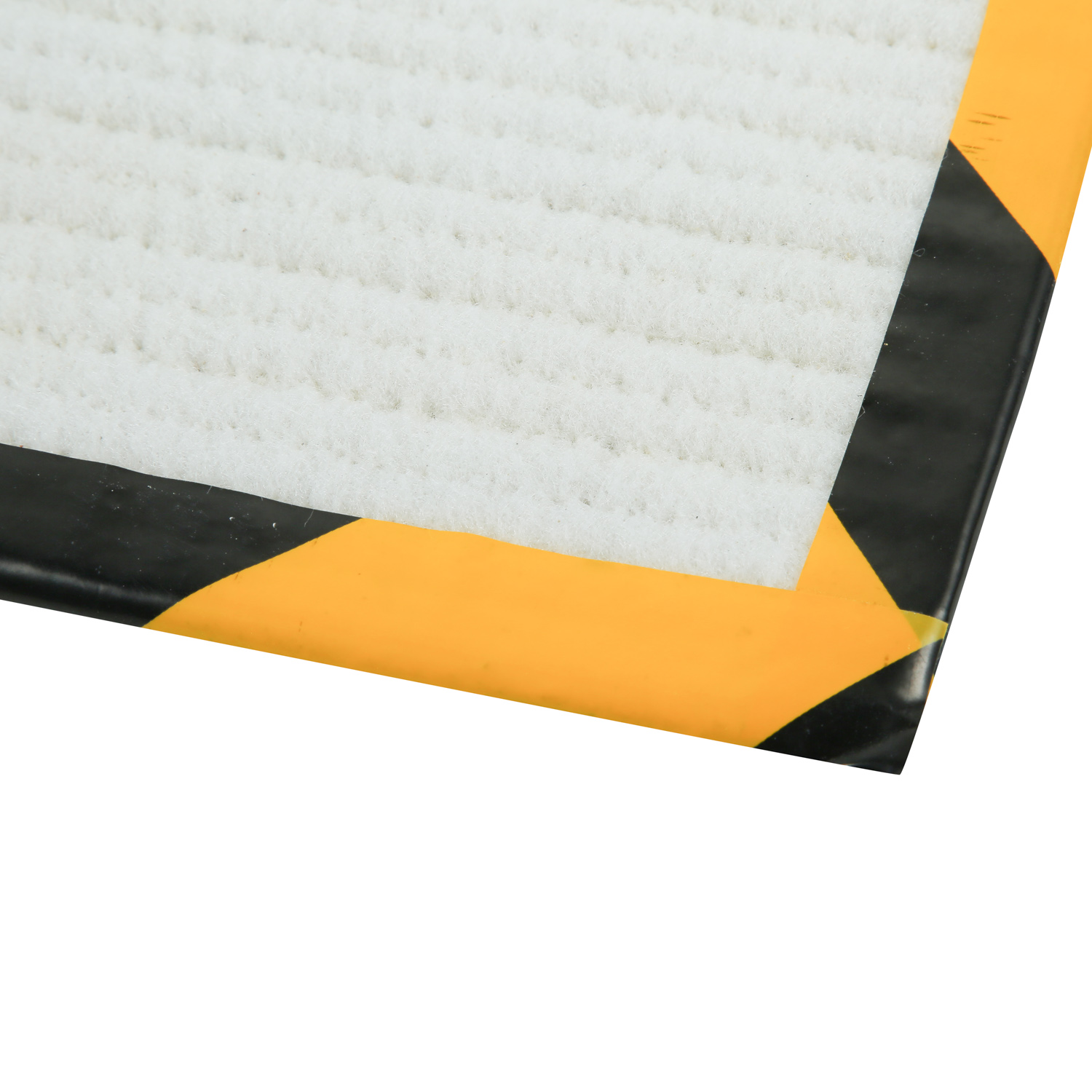

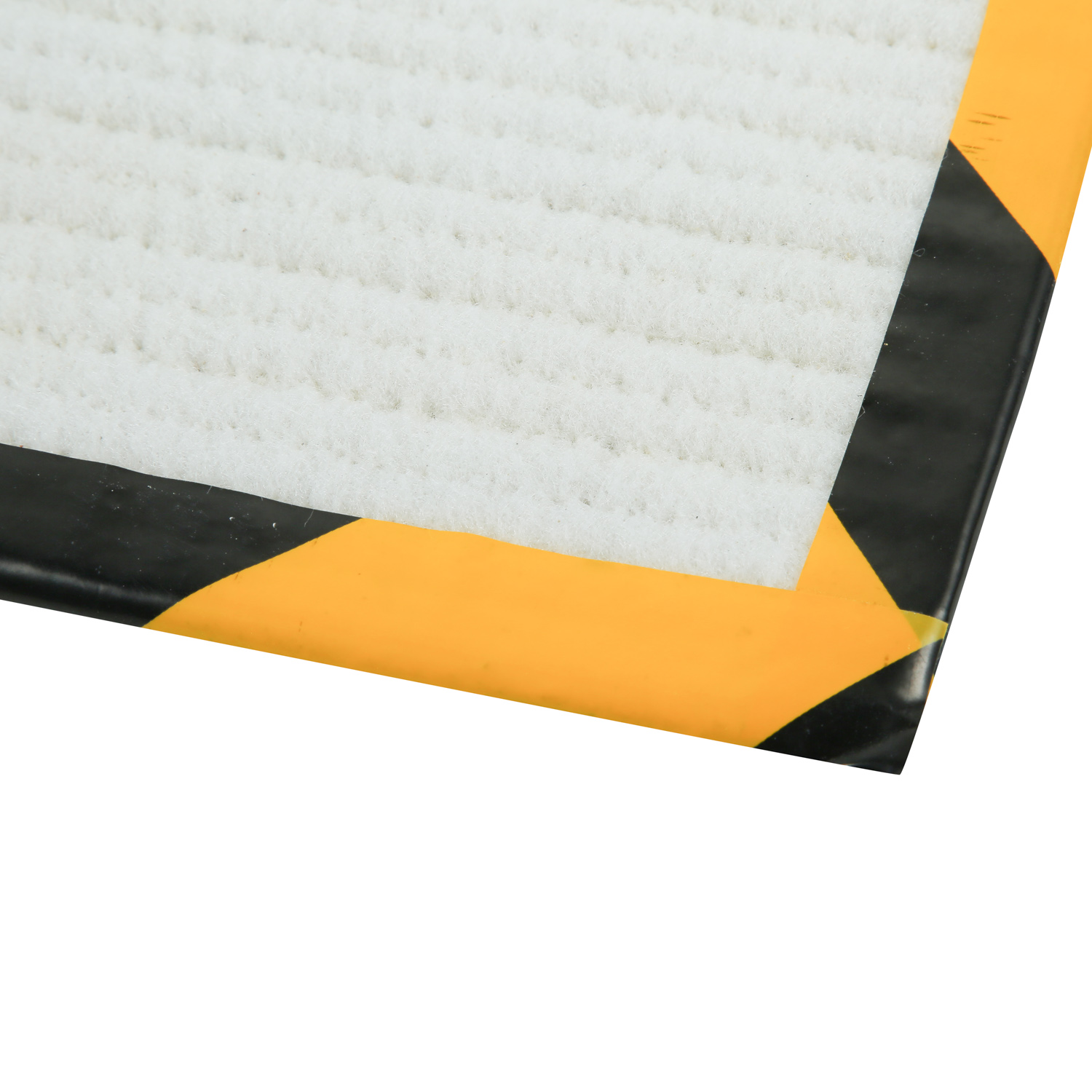

Geosynthetic Clay Liners are high performance needle punched environmental reinforced composites which combine two durable geotextile outer layers with a uniform core of natural sodium bentonite clay to form a hydraulic barrier.

For different projects,it can combine HDPE liner for better waterproof. When hydrated under a confining load, the bentonite swells to form a low permeability clay layer with the equivalent hydraulic protection of several feet of compacted clay. The excellent properties of tensile and peel strength make the products ideal for many projects.

Technique Data:

| Property | National standard | Enterprise Standard | Inspection standards |

| JG/T 193-2006 | |||

| Geosynthetic Clay Expansionindex | ≥24 ml/2g | ≥25ml/2g | ASTM D5890 |

| Mass Per Unit Area(g/m2) | ≥4800 g/m2 | ≥4800 gm2 | ASTM D5993 |

| Tensile Strength | ≥6KN/m | ≥8KN/m | ASTM 4632 |

| Maximum load elongation | ≥10% | ≥10% | ASTM 4632 |

| Permeability | ≤5×10-9 | ≤5×10-9 | ASTM D5084 |

| Moisture content | ≤15% | ≤15% | ASTM D4643 |

| Peel strength | ≥40N | ≥65N | ASTM D4632 |

| Hydrostatic pressure | 0.4Mp | 0.4~0.6Mp | ASTM D5891 |

Features :

1.The permanent waterproof

Because sodium base bentonite is a natural inorganic material, even after a long time or the surrounding environment changes,

also won't happen aging or corrosion phenomena, so the waterproof performance persistence.

2. Compactibility

Sodium base bentonite under water pressure condition to form diaphragm with high density, thickness of about 3 mm,

its permeability is 5 x 10-11m/SEC below, equivalent to 100 times the compactness of 30 cm thickness of clay,

have very strong since the water retention performance.

3.Not affected by temperature

In cold climates will not brittle fracture.

4.Environmental protection

Bentonite as natural inorganic material, non-toxic harmless to human body, no special effects to the environment,

have good environmental performance.

5.Simple and short time of construction

Compared to other waterproofing materials, construction is relatively simple, don't need to be heated and paste.

With bentonite powder and nails, washers, etc are connected and fixed. After construction does not need special

inspection, if it is found that the waterproof defects and easy to maintenance.

GCL is existing waterproof material in construction period of the shortest.

Product Description

Bentonite waterproof liner (GCL) is a new geosynthetic material. Taking natural sodium bentonite as material, bentonite particles are fixed between two layers of geotextile by special process to make bentonite waterproof blanket, which not only has all the characteristics of geotechnical materials, but also has excellent waterproof (seepage) performance.

Specification

1. GCL-NP, GCL-OF;

2. Unit weight: ≥4000g/sm;

3. 4m-6m in roll width;

4.length can be produced as your requirement.

| Projects/ Technical data | Specifications | |

| GCL-NP | GCL-OF | |

| Weight per unit area(g/m2) | ≥4000g/m2 | |

| Bentonie swell index(ml/2g) | ≥24 | ≥24 |

| Ethylene blue absorption(g/100g) | ≥30 | ≥30 |

| Tensile strength (N/100mm) | ≥600 | ≥700 |

| Racking strength(N/100mm) (for nonwovwn and woven fabric) | ≥40 | ≥40 |

| Racking strength(N/100mm) (for HDPE films and nonwoven fabric) | ≥30 | |

| Permeability(m/s) | ≤5.0x110^(-11) | ≤5.0x110^(-11) |

| Anti-static water pressure | 0.4Mpa,1h, not seepage | 0.6Mpa,1h,not seepage |

| Filtration loss (ml) | ≤18 | ≤18 |

| Bentonite durability (ml/2g) | ≥20 | ≥20 |

Features:

1. Improved leakage performance;

2. Permanent waterproof performance;

3. Simple construction and short time limit for a project;

4. Not influenced by air temperature;

5. A kind of green material and good to environmental protection;

6. More versatile than compacted clay;

7. Increased airspace and liner efficiency.

Application:

| · Landfills | · Mud Pits |

| · Lagoons | · Canals |

| · Bund Lining | · Tank Lining |

| · Fish Farm Lining | · Roof Lining |

| · Waste Water Pits | · Ponds and Reservoirs |

| · Dams | · Floating Covers |

| · Vertical Cutoff Walls | · Hydraulic Structure |

| · Basement Lining | · Drip Irrigation Ponds |

Geosynthetic Clay Liners are high performance needle punched environmental reinforced composites which combine two durable geotextile outer layers with a uniform core of natural sodium bentonite clay to form a hydraulic barrier.

For different projects,it can combine HDPE liner for better waterproof. When hydrated under a confining load, the bentonite swells to form a low permeability clay layer with the equivalent hydraulic protection of several feet of compacted clay. The excellent properties of tensile and peel strength make the products ideal for many projects.

Technique Data:

| Property | National standard | Enterprise Standard | Inspection standards |

| JG/T 193-2006 | |||

| Geosynthetic Clay Expansionindex | ≥24 ml/2g | ≥25ml/2g | ASTM D5890 |

| Mass Per Unit Area(g/m2) | ≥4800 g/m2 | ≥4800 gm2 | ASTM D5993 |

| Tensile Strength | ≥6KN/m | ≥8KN/m | ASTM 4632 |

| Maximum load elongation | ≥10% | ≥10% | ASTM 4632 |

| Permeability | ≤5×10-9 | ≤5×10-9 | ASTM D5084 |

| Moisture content | ≤15% | ≤15% | ASTM D4643 |

| Peel strength | ≥40N | ≥65N | ASTM D4632 |

| Hydrostatic pressure | 0.4Mp | 0.4~0.6Mp | ASTM D5891 |

Features :

1.The permanent waterproof

Because sodium base bentonite is a natural inorganic material, even after a long time or the surrounding environment changes,

also won't happen aging or corrosion phenomena, so the waterproof performance persistence.

2. Compactibility

Sodium base bentonite under water pressure condition to form diaphragm with high density, thickness of about 3 mm,

its permeability is 5 x 10-11m/SEC below, equivalent to 100 times the compactness of 30 cm thickness of clay,

have very strong since the water retention performance.

3.Not affected by temperature

In cold climates will not brittle fracture.

4.Environmental protection

Bentonite as natural inorganic material, non-toxic harmless to human body, no special effects to the environment,

have good environmental performance.

5.Simple and short time of construction

Compared to other waterproofing materials, construction is relatively simple, don't need to be heated and paste.

With bentonite powder and nails, washers, etc are connected and fixed. After construction does not need special

inspection, if it is found that the waterproof defects and easy to maintenance.

GCL is existing waterproof material in construction period of the shortest.

Product Description

Bentonite waterproof liner (GCL) is a new geosynthetic material. Taking natural sodium bentonite as material, bentonite particles are fixed between two layers of geotextile by special process to make bentonite waterproof blanket, which not only has all the characteristics of geotechnical materials, but also has excellent waterproof (seepage) performance.

Specification

1. GCL-NP, GCL-OF;

2. Unit weight: ≥4000g/sm;

3. 4m-6m in roll width;

4.length can be produced as your requirement.

| Projects/ Technical data | Specifications | |

| GCL-NP | GCL-OF | |

| Weight per unit area(g/m2) | ≥4000g/m2 | |

| Bentonie swell index(ml/2g) | ≥24 | ≥24 |

| Ethylene blue absorption(g/100g) | ≥30 | ≥30 |

| Tensile strength (N/100mm) | ≥600 | ≥700 |

| Racking strength(N/100mm) (for nonwovwn and woven fabric) | ≥40 | ≥40 |

| Racking strength(N/100mm) (for HDPE films and nonwoven fabric) | ≥30 | |

| Permeability(m/s) | ≤5.0x110^(-11) | ≤5.0x110^(-11) |

| Anti-static water pressure | 0.4Mpa,1h, not seepage | 0.6Mpa,1h,not seepage |

| Filtration loss (ml) | ≤18 | ≤18 |

| Bentonite durability (ml/2g) | ≥20 | ≥20 |

Features:

1. Improved leakage performance;

2. Permanent waterproof performance;

3. Simple construction and short time limit for a project;

4. Not influenced by air temperature;

5. A kind of green material and good to environmental protection;

6. More versatile than compacted clay;

7. Increased airspace and liner efficiency.

Application:

| · Landfills | · Mud Pits |

| · Lagoons | · Canals |

| · Bund Lining | · Tank Lining |

| · Fish Farm Lining | · Roof Lining |

| · Waste Water Pits | · Ponds and Reservoirs |

| · Dams | · Floating Covers |

| · Vertical Cutoff Walls | · Hydraulic Structure |

| · Basement Lining | · Drip Irrigation Ponds |