400-1200g/m2

Yingfan

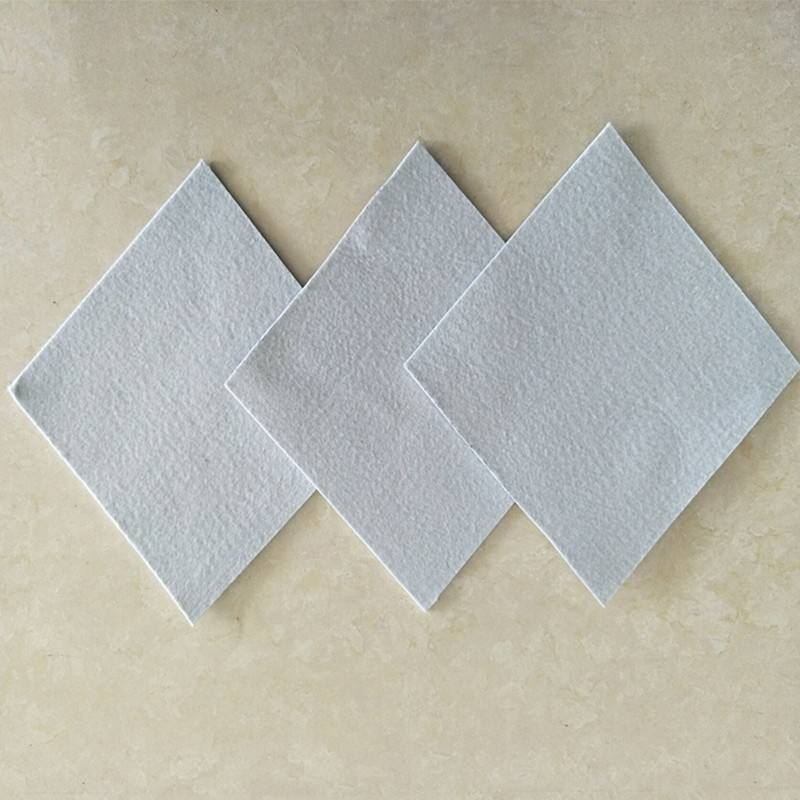

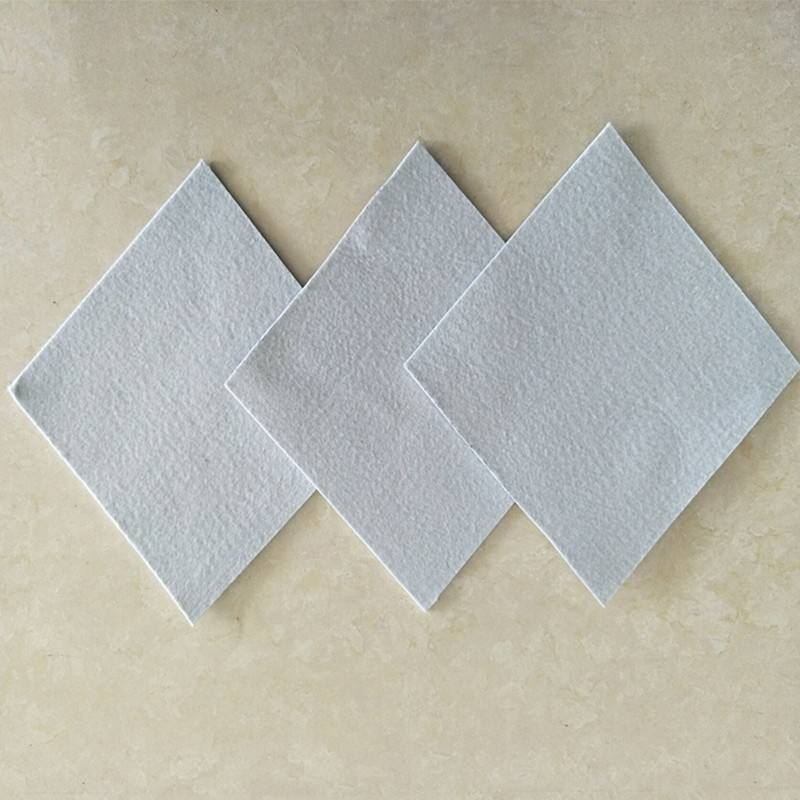

By using calendaring processing technology, composite geomembrane liners are created by heat-bonding nonwoven or woven geotextiles with HDPE geomembranes. Using a continuous far infrared ray heating oven, composite geomembrane liners are formed by pressing a geotextile layer over the geomembrane layer. At the same time, polymer and anti-aging materials are added to the manufacturing process, so they can be used in unconventional temperatures.

Composite Geomembrane Liner combines the benefits of geotextiles and geomembranes, granting enhanced tensile strength and an outstanding impermeability. Its robust, leak-proof, moisture resistant design makes it the ideal choice to reduce potential leakage from any small seep holes in a municipal solid waste system. This type of liner is employed for various purposes such as landfills, waste water treatment, roads construction, aquaculture, landscape and agriculture.

Composite Geomembrane Liner Specification

| Test Item | Test Properties | Unit | JC | JC5 | JC6 | JC7 | JC8 |

| Weight | g/m2 | 400 | 500 | 600 | 700 | 800 | |

| Film Thickness | mm | 0.25-0.35 | 0.30-0.50 | ||||

| Mechanical Properties | Break Strength | kN/m | 5.0 | 7.5 | 10 | 12 | 14 |

| Break Elongation | % | 30-100 | 30-100 | 30-100 | 30-100 | 30-100 | |

| CBR Burst Strength | KN | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | |

| Tear Resistance | KN | 0.15 | 0.25 | 0.32 | 0.4 | 0.48 | |

| Peel Strength | N/cm | ≥6 | ≥6 | ≥6 | ≥6 | ≥6 | |

| Hydrostatic Pressure | Film Thickness | mm | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 |

| One cloth one film | MPa | 0.4 | 0.5 | 0.6 | 0.8 | 1 | |

| Two cloth one film | MPa | 0.5 | 0.6 | 0.8 | 1 | 1.2 |

High tensile strength.

Excellent chemical resistance.

Effective drainage and waterproof performance.

Excellent impermeable, leak and moisture proof.

Excellent UV resistance.

Excellent tear and puncture resistance.

Stable low temperature embrittlement resistance.

Easy to deploy.

Cost saving.

Anti-aging and anti-corrosion.

By using calendaring processing technology, composite geomembrane liners are created by heat-bonding nonwoven or woven geotextiles with HDPE geomembranes. Using a continuous far infrared ray heating oven, composite geomembrane liners are formed by pressing a geotextile layer over the geomembrane layer. At the same time, polymer and anti-aging materials are added to the manufacturing process, so they can be used in unconventional temperatures.

Composite Geomembrane Liner combines the benefits of geotextiles and geomembranes, granting enhanced tensile strength and an outstanding impermeability. Its robust, leak-proof, moisture resistant design makes it the ideal choice to reduce potential leakage from any small seep holes in a municipal solid waste system. This type of liner is employed for various purposes such as landfills, waste water treatment, roads construction, aquaculture, landscape and agriculture.

Composite Geomembrane Liner Specification

| Test Item | Test Properties | Unit | JC | JC5 | JC6 | JC7 | JC8 |

| Weight | g/m2 | 400 | 500 | 600 | 700 | 800 | |

| Film Thickness | mm | 0.25-0.35 | 0.30-0.50 | ||||

| Mechanical Properties | Break Strength | kN/m | 5.0 | 7.5 | 10 | 12 | 14 |

| Break Elongation | % | 30-100 | 30-100 | 30-100 | 30-100 | 30-100 | |

| CBR Burst Strength | KN | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | |

| Tear Resistance | KN | 0.15 | 0.25 | 0.32 | 0.4 | 0.48 | |

| Peel Strength | N/cm | ≥6 | ≥6 | ≥6 | ≥6 | ≥6 | |

| Hydrostatic Pressure | Film Thickness | mm | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 |

| One cloth one film | MPa | 0.4 | 0.5 | 0.6 | 0.8 | 1 | |

| Two cloth one film | MPa | 0.5 | 0.6 | 0.8 | 1 | 1.2 |

High tensile strength.

Excellent chemical resistance.

Effective drainage and waterproof performance.

Excellent impermeable, leak and moisture proof.

Excellent UV resistance.

Excellent tear and puncture resistance.

Stable low temperature embrittlement resistance.

Easy to deploy.

Cost saving.

Anti-aging and anti-corrosion.